Engraved Decora Covers

(800) 482-1553

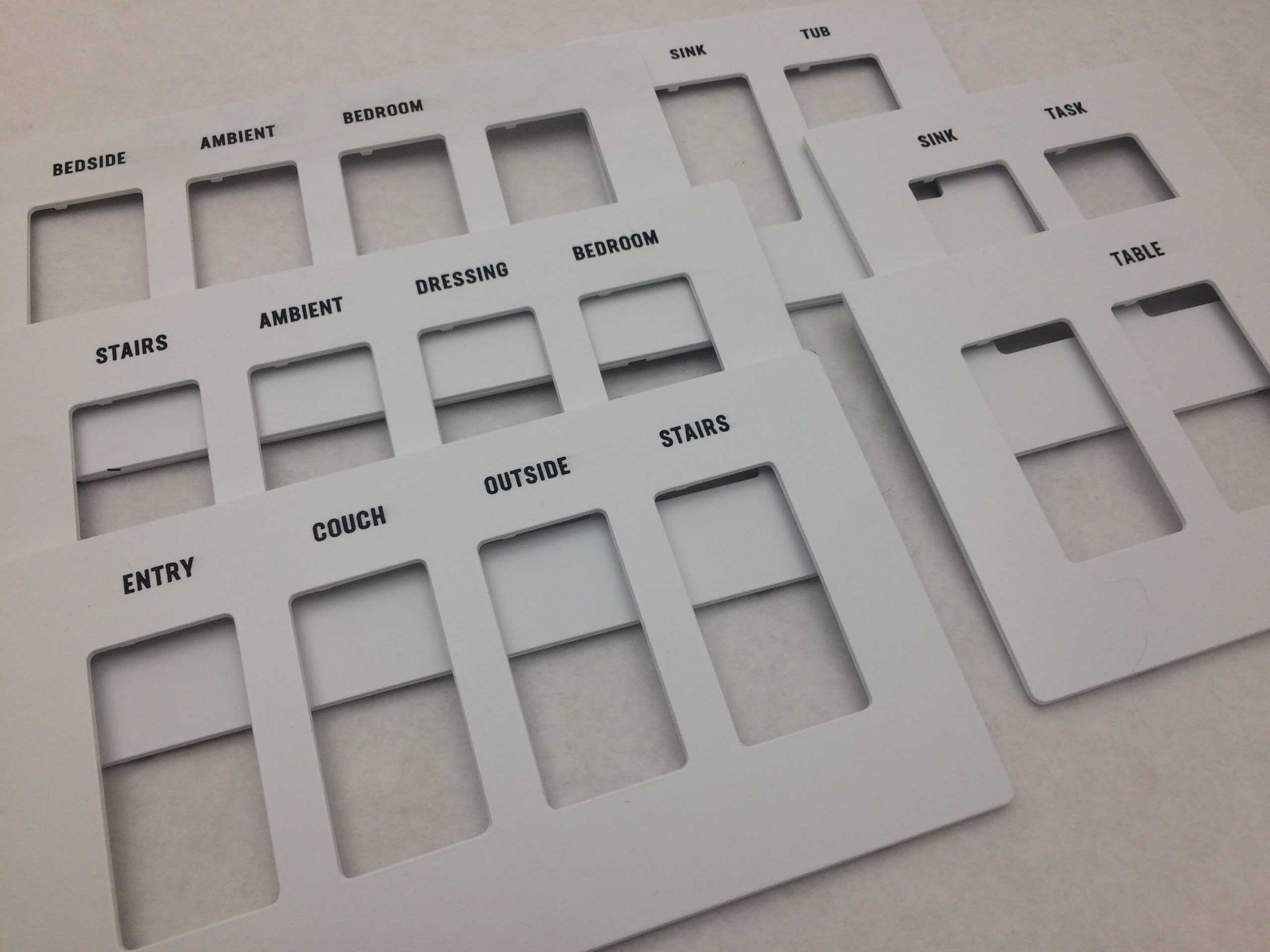

Considering Engraved Decora Covers In industrial and manufacturing environments, the effective identification of outlets is crucial to ensure the proper functioning of machinery and equipment. In this context, laser engraving has emerged as a practical and versatile solution for creating precise and enduring markings on various surfaces. Explore the diverse applications of Laser Engraved Decora covers and delves into the unique capabilities of Laser Engraving Pros in providing customized solutions.

Order – Engrave – Pack – Ship : All Faster than the Big Guys can get Your First Name!

Engraved Decora Covers for Enhanced Functionality

In any industrial or manufacturing setting, the accurate identification of controls is essential to minimize errors and enhance operational efficiency. Laser Engraving Pros, with a rich history of excellence, specializes in creating engraved Decora covers, utilizing a range of laser machines capable of engraving on diverse surfaces. The focus on stainless steel covers showcases the dedication to delivering quality products, with the ability to tailor engraving depth and darkness according to specific requirements.

The Role of Proper Labeling in Industrial Settings

Proper labeling of electrical components, including Decora covers, plays a vital role in maintaining a safe and organized work environment. Compliance with industry-specific regulations ensures that workplaces adhere to safety standards. We recognize the importance of accurate labeling and commits to providing Engraved Decora covers that meet both regulatory requirements and individual preferences.

Laser Engraving Pros : A Legacy of Excellence

With production dating back to the 1890s, Laser Engraving Pros has been an integral part of the community, catering to the needs of individuals and large businesses alike. The commitment to personalized service is evident in their acceptance of special requests and deadlines, emphasizing the value placed on building lasting relationships with customers. Clients can expect precision and professionalism from a team dedicated to their craft.

Versatility in Orders and Shipping

LaserEngravingPros offers a tailored approach to every order, accommodating requests of all sizes. Clients have the flexibility to provide their own materials for engraving, with the option to ship items directly to the facility. The ability to handle orders ranging from individual items to bulk shipments, delivered globally via UPS, showcases the company’s commitment to meeting diverse customer needs.

The Engraving Process Unveiled

ENGRAVINGSWITCHPLATESNOW.COM serves as a platform to showcase Laser Engraving Pros’ capabilities in engraving all types of device covers. Utilizing high-end processing software, the company seamlessly integrates data into their engraving systems, providing clients with proofs before production. Custom-designed equipment facilitates the engraving process, ensuring ease and precision.

Diverse Options for Engraving

We specializes in a variety of switch plates, including custom Wall Plates, GFI Plates, single and double-gang Switch Plates Covers, and receptacle plates. The ability to paint-fill these plates adds an extra layer of customization. The company’s expertise in engraving high-capacity and automated laser-marked switch plates ensures efficiency, even offering quick engraving services for aluminum, steel, or plastic plates.

Advancements in Laser Engraving Technology

The laser engraving process employs a high-powered laser beam to etch patterns onto materials such as stainless steel, metal, nylon, and plastic. Beyond etching, the laser can paint-fill circuit numbers and panel identifiers onto the surface, ensuring enduring and legible identification. Laser engraving allows for a level of detail and customization that traditional methods struggle to achieve. The ability to engrave variable data directly onto materials caters to specific project requirements, whether it’s circuit numbers, panel numbers, or other identifiers.

Looking Ahead: Future Innovations in Laser Engraving

As technology advances, laser engraving techniques are poised to evolve further. Anticipated innovations include enhanced speed, increased material compatibility, and additional features pushing the boundaries of current capabilities. Staying abreast of these advancements is crucial for industries relying on laser engraving for identification purposes.

Sustainability and Efficiency

Laser engraving your companies device covers emerges as a multifaceted solution combining precision, durability, cost-effectiveness, and efficiency. The technology’s applications extend across various industries, providing benefits that address practical and environmental considerations. The permanence of laser-engraved markings contributes to sustainability by reducing the need for disposable labels or decals, aligning with environmentally conscious practices.

The Environmental Impact of Laser Engraving

Laser engraving’s efficiency stands out in comparison to traditional methods like labeling or decaling. It proves cost-effective over time, eliminating the need for periodic label replacement and providing a durable solution. Laser engraving ensures heightened accuracy, expediting the process with a faster turnaround. While upfront costs may be involved, the long-term savings and enduring results make laser engraving a superior choice for marking Decora covers.

Permanent and Enduring Markings

One of the primary advantages of laser engraving is the creation of permanent and enduring markings. Unlike labels or decals prone to degradation, laser-engraved identifications remain intact, providing a long-lasting solution. In environments where durability is paramount, such as industrial settings or high-traffic areas, laser engraving proves indispensable.

Efficiency in Electrical Projects

Laser engraving nylon Wall Plates specifically benefits electricians and electrical inspectors by simplifying the installation process. Clear and legible markings enable quick and accurate identification of receptacles, saving time during installation and contributing to overall project timelines. The direct engraving of variable data into the material itself eliminates reliance on labels or decals that may fade or be removed due to wear and tear.

The Transformative Impact on Receptacle Covers

Laser engraving has transformed the identification of receptacle covers in both government buildings and private homes. Moving away from labels or decals that may degrade over time, laser engraving allows for the direct engraving of variable data into the material itself. This permanence not only reduces waste but also aligns with environmentally conscious practices, contributing to sustainability.

Cost-Effectiveness of Laser Engraving

While upfront costs for equipment and technology are involved, laser engraving proves cost-effective in the long run. Traditional methods often require periodic label replacement, incurring ongoing expenses. Laser-engraved markings eliminate the need for such replacements, resulting in long-term savings. The enduring and detailed solution provided by laser engraving ensures its relevance, making it an indispensable tool in any electrical project.

PO’s OK! – NO MINIMUM ORDER – Get a Free Sample

In the realm of engraved Decora covers, Laser Engraving Pros stands out as a provider of precision, efficiency, and sustainability. The article has explored the multifaceted applications of laser engraving technology, emphasizing its advantages over traditional methods. As technology continues to evolve, the future promises even more sophisticated solutions, solidifying laser engraving a position as a transformative and enduring identification tool.

Got A Project? Send Us the Info and Let us Get Started!

Contact Us -or- Order A Sample