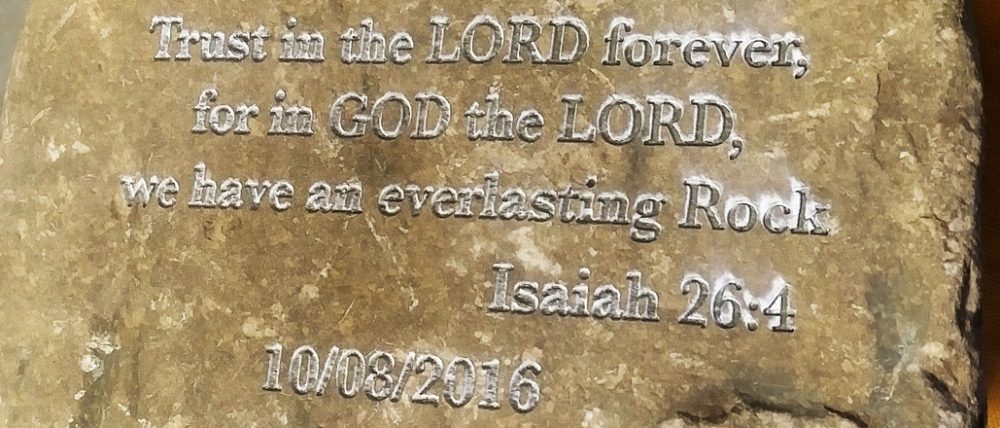

This is the story of a tree. It ends with a beautiful piece of engraved wood, which is a very happy ending for a tree, but we’re not there yet. Right now, we have a lovely, strong tree, just waiting to be fulfilled. So how do we get from there to that custom piece of engraved wood? Follow along and we’ll tell you! First, the tree is cut down and processed. Many trees in this situation are destined to become particle board, paper or even just pulp, but not our tree! Its attractive shape and color have marked it for better things. Our tree is carved into thick boards, polished to show its grain off to best effect, and stained to enhance its natural beauty. All of this is a good start, but the final touch comes from the burning kiss of a laser. That’s what finally takes it to the engraved wood we mentioned at the start!

That’s also where we come into this process. We’re not lumberjacks, and we’ve never been in a lumber mill in our lives. But we can wield a laser like no one else, and we’ve made some fine engraved wood in our time! In fact, it’s fair to say that we make the best engraved wood around. How are we so good? Years of focused practice. Back when other kids were just carving their initials into trees, we were already turning blank plaques into engraved wood. That kind of dedication shows! And we’re ready to put our services to work for you. So if you’re looking for engraved wood, fill out the RFQ form below and we’ll get you a custom quote on the double. Help that tree reach its potential!