Metal Cutting Laser Gilbert

Metal Cutting. . .with Lasers! In Gilbert!

Remember that future where they promised each and every one of us everyone would get a jetpack? LIES! . . .But at least we can play with lasers while we wait. We have lasers, lots and lots of lasers, but we want more, so until we can afford a laser big enough to hold the moon hostage, we’re using our lasers for good (Ugh) and offering Metal Cutting by Laser in Gilbert!

Here at LASER ENGRAVING PROS, we have LASER BEAMS OF FIRE AND FURY, prepared to do the bidding of our clients in Gilbert!

Lasers are Kind of Our Thing

The process is as fun as the product: Laser cutting technology vaporizes just about any kind of material, resulting in a precision-cut edge. While in the past, only industrial manufacturers and Bond villains bent on global domination could afford lasers, the industry has evolved and costs decreased enough to make laser-cut products affordable for the full range of Gilbert businesses, from heavy industries to a range of government customers, or really cool small businesses and niche architectural customers.

Metal Cutting Laser; It’s not Just Aliens, Gilbert. . .This Time.

Today, LASER ENGRAVING PROS lets you use our LASER BEAM OF FIRE AND FURY to etch our Gilbert clients’ products into the lasting memory of foe and client alike. We have the MOST POWERFUL metal cutting lasers commercially available. And we work to your custom specifications, on super-tight turnaround, and ship it straight to your door.

We’re Less Likely to Use Our Lasers to Destroy a City than Our “Competition”!

This is not to suggest your commercial or personal project is any less significant than a conniving Bond villain’s, but let’s acknowledge you’re less likely to demand a $1 billion ransom to prevent your laser beam from smoking Paris off the map.

So are we! LASER ENGRAVING PROS may HOLD IN ITS GRASP THE POWER OF A FULLY-OPERATIONAL DEATH STAR, but we’re committed to sharing that power with our Gilbert customers – and making it easy on your wallet.

Metal Cutting Lasers with the Real, Ultimate Power

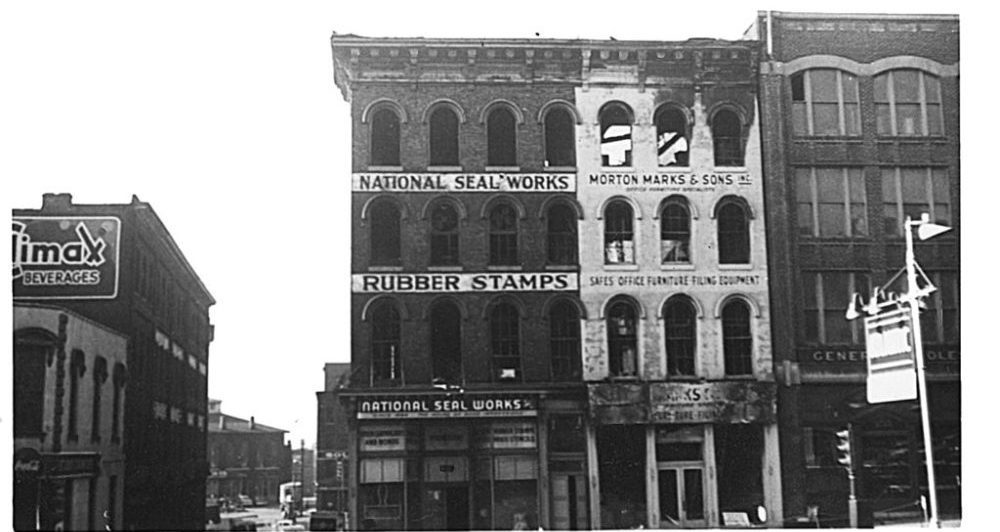

We’ve been sharing that Real Ultimate Power for a long time, too. Laser Engraving Pros, at its heart (as dead set as it may be on global domination), remains a small family-owned business, founded in 1891. But not stuck in 1891! We like new toys – new lasers!

We’ve got the Fire You Desire!

The modern industrial laser works by directing the output of a high-power laser focused through precision optics. This optically-focused beam then are directed via CNC (computer numerical control) to direct the path of the laser beam at the material being cut – be that a new sign for your business, a piece of heavy plating that will become armor, or James Bond’s crotch.

A commercial laser for cutting materials uses a motion control system to follow the pattern laid out for the material by the CNC program. The focused laser beam either melts, burns, vaporizes away, or gets blown away – did we mention our LASER BEAM OF FIRE & FURY?

The Focused and Furious (And Fast!)

While furious and fiery, that doesn’t mean we can’t focus. In fact, focus is what determines quality when it comes to lasers. The narrowest part of the focused beam is generally less than 0.0125 inches (0.32 mm) in diameter. Depending upon the material thickness, “kerf” widths as small as 0.004 inches (0.10 mm) are possible. You don’t need to know what a kerf is. Because we do! Suffice to say, they’re not very wide.

In order to be able to start cutting, the laser first has to pierce the object. Piercing usually involves a high-power pulsed laser beam. This is not the instant death rays of sci-fi. Instead, the laser takes around 5–15 seconds to zap, for instance, through 0.5-inch-thick (13 mm) stainless steel. It might take longer the thicker the object is.

Metal Cutting Laser, Gilbert!

Here at LASER ENGRAVING PROS, we’re not satisfied resting on our laurels – or our lasers. So we’re constantly looking to expand our arsenal, bent on global domin…. I mean, on producing custom, quality work for Gilbert businesses.

For Metal Cutting Lasers in Gilbert, We’re Fixated on Fiber

Fiber lasers are our latest fascination. A type of solid-state laser rapidly growing within the metal cutting industry, Fiber lasers use a solid medium, as opposed to a gas or liquid, to power them. Also called a “seed laser”, these lasers are amplified within a glass fiber – think fiberoptic, but with the DESTRUCTIVE FORCE CAPABLE OF VAPORIZING A PLANE… that is, capable of even greater precision in making quality products for you, our Gilbert clients. With a wavelength of only 1064 nanometers, fiber lasers produce an extremely small spot size (up to 100 times smaller compared to the CO2), making it ideal for cutting reflective metal material. This is one of the main advantages of Fiber compared to CO2.

Metal Cutting Lasers in Gilbert is Your Friend–with Benefits!

Fiber laser cutter benefits include:

- Rapid processing times.

- Reduced energy consumption & bills – due to greater efficiency.

- Greater reliability and performance – no optics to adjust or align and no lamps to replace.

- Minimal maintenance.

- The ability to process highly reflective materials such as copper and brass.

- Higher productivity – lower operational costs offer a greater return on your investment.

Burn things with Fire and Fury, Gilbert!

But also make a lasting impression with the quality you and your customers – or your arch-nemeses – have come to expect. Metal Cutting Laser Gilbert – The Best in Precision and Power!