Laser Engraving Columbia

Hello, Columbia!

After 135 years of building a reputation as the national go-to for engraving and cutting metal and just about anything your business cares to imagine, Laser Engraving Pros is setting up shop and putting down roots in Columbia, South Carolina! Established in 1891, our five-generation company treats Laser Engraving as mission-critical to the work you do. Tags and plates that provide critical information must survive heat, humidity, abrasion, solvents, and just plain old wear and tear, ready for inspection or for use regardless of age. Projects go off the rails when identifiers fade or flake. Laser Engraving Pros lets you – and everyone who depends on you – sleep at night.

Columbia is a capital town. And coming as we do from another Southern capital city, we know that tradition, precision and professionalism take top priority here. We honor those priorities. Soda City has a long tradition as a leader in industry and innovation, and so does Laser Engraving Pros. Technology expands, energy projects scale, and logistics demand clarity at speed. In a climate known for heat swings and sudden storms, identification either endures or it doesn’t. Our Laser Engraving endures. Our team receives shipments daily, and we deliver to nearby cities around Columbia with the same strict controls.

We are a small, exceptional, All-American staff of highly trained specialists in our work. We take pride in making products that protect your compliance and reputation. All of our tag materials are sourced and manufactured in the United States. That decision keeps our quality – and yours – traceable, repeatable, and accountable. And it honors American jobs. Our pricing is always competitive – and always without empty promises or flashy gimmicks. The majority of our customers choose us because a lack of compliance can be far more costly than precision.

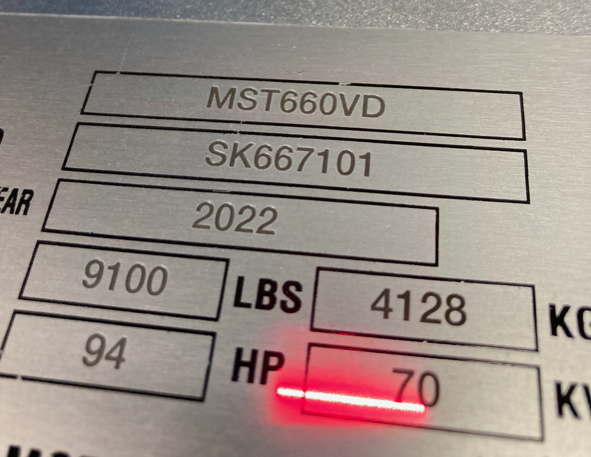

We’ve already moved in and turned on the lights, but we’re still arranging the furniture – less easy than you’d think when some of that furniture is industrial lasers… But for a wee bit, this means the office is by appointment only.

Service First: Laser Engraving that won’t quit, Columbia

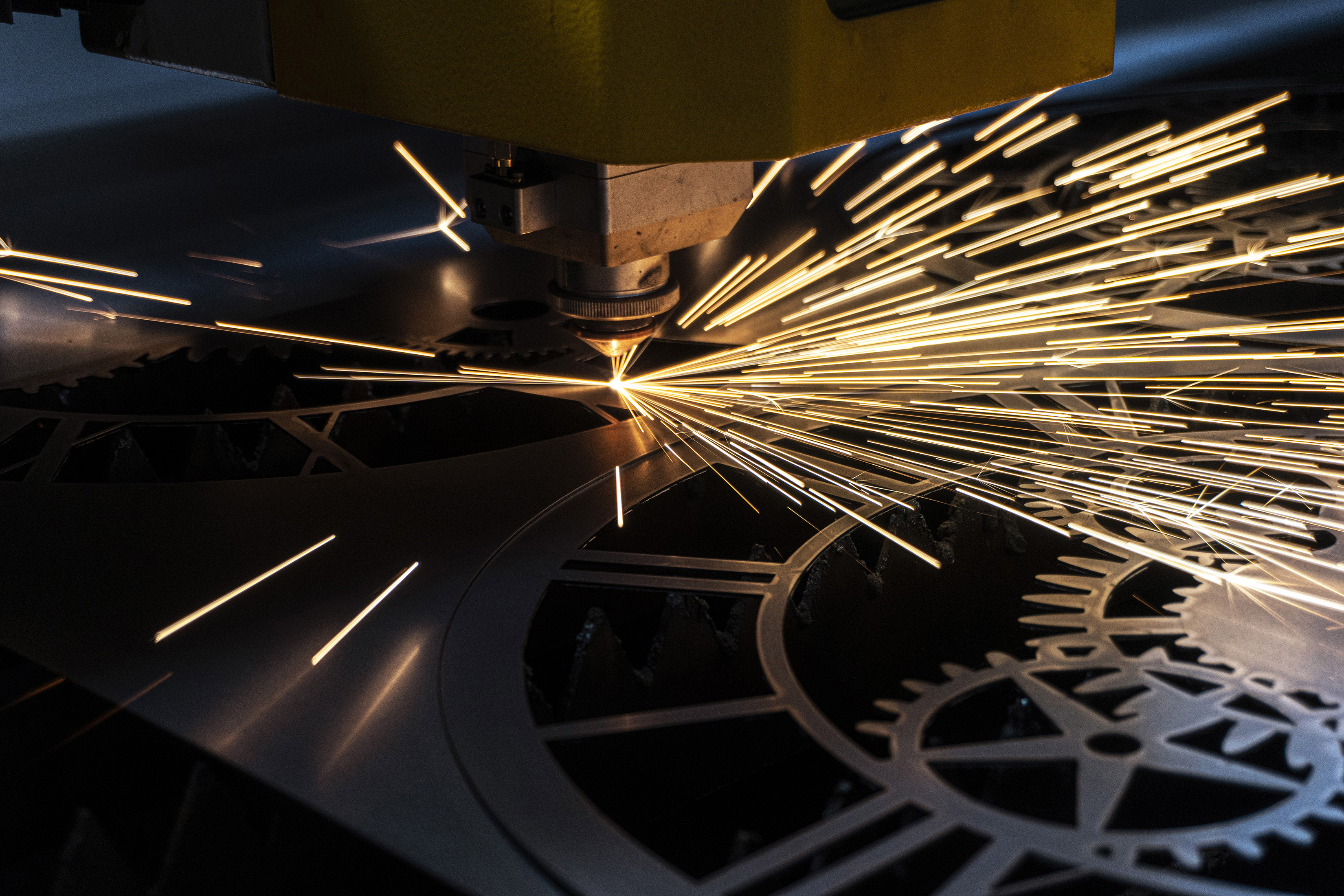

Our focus is lasers. We eat, sleep and live lasers – so you don’t have to. Disclaimer: Eating lasers isn’t a recommended nutritional suppliment. But what our poor dietary choices means – besides indigestion – is you get the goods. Your project – every parameter around readability, permanence, and audit confidence – will be right the first time.

We can engrave anything: Stainless steel? Yes indeed. Steel? Absolutely covered. Need aluminum? We do that, too. Anodized aluminum? Yup. Copper, titanium, polymer, and engineered plastics and acrylics? All day, yes way. When your scope requires cutting or marking in tandem, we also provide laser cutting and laser etching as integrated services, keeping tolerances tight and documentation clean.

UL Approved identifiers matter. UL approval signals that engraved information meets specific durability and safety criteria recognized by inspectors. For regulated programs, we configure materials, finishes, adhesives, and engraving settings to align with UL recognition pathways and required permanence tests. That alignment turns “should pass” into “will pass,” and inspectors notice.

Why leaders in Columbia rely on our service

Data centers need engraved rack maps, panel legends, and asset identifiers that stay readable. Solar farms, wind farms, and every solar array in hard sun require durable contrast on PV tags and solar tags that shrug off UV and rain. Aerospace and defense programs demand serialization that survives fuel, hydraulic fluids, and salt spray. Industrial equipment lives through vibration, impact, and chemical washdowns. Our Laser Engraving is specified for these realities because it keeps your traceability intact when conditions turn hostile.

We understand the language of serious procurement. If your RFQ mentions phrases like qualified subcontractor laser engraving defense, MIL-SPEC laser marking supplier, ITAR certified metal engraving, precision laser cut metal components aerospace supplier, supplier diversity qualified metal parts subcontractor, RFQ laser engraving / laser cut tags for defense equipment, or supplier qualification aerospace tier 1? We speak that language fluently. We build our service to satisfy that intent—repeatable process, documented control, clean records—without theatrics.

Uses, types, and advantages of Laser Engraving

Laser Engraving supports compliance labeling, serialized metal tags, equipment nameplates, warning plates, schematic legends, gauge faces, and precision component identification for aircraft, drones, turbines, rotorcraft, missile systems, naval hardware, electronics, sensors, avionics, propulsion assemblies, and corrosion-resistant tags on assemblies exposed to harsh conditions. In medical environments, engraving supports FDA-compliant device identification and process visibility. In automotive and industrial settings, it preserves lot tracking through heat cycles, solvents, and physical abuse.

Two essential lists

- Types of Laser Engraving we deliver

- Deep engraving for extreme abrasion and long-life tooling

- High-contrast black marking on stainless for scanners and human eyes

- Fine detail micro-engraving for compact electronics identifiers

- Chemical-resistant engraving for fuels, cleaners, and hydraulic fluids

- UID / 2D code engraving with verification-driven contrast targets

- Benefits of engineered Laser Engraving

- Survives heat, humidity, chemicals, and abrasion

- Preserves traceability through maintenance and overhaul

- Reduces audit exposure and warranty disputes

- Speeds service by keeping identifiers readable under stress

- Projects professionalism with crisp, consistent marks

Materials: What Works, When, and Why in Columbia?

Stainless steel resists corrosion and abrasion in the field. Choose it for coastal humidity, chemical exposure, or where failure is unacceptable. Steel provides strength and value but needs finishing to resist corrosion; for long-term outdoor duty, stainless or anodized aluminum often wins. Aluminum delivers light weight and responsiveness to engraving; for elevated UV resilience and colorfastness, anodized aluminum excels because its anodic layer locks in contrast. Copper offers conductivity and distinctive look; in humid conditions it will oxidize, so plan for patina or select stainless. Titanium handles high heat and specialty aerospace or medical needs. Polymer and acrylic assist where weight, electrical isolation, or internal environments dominate—yet plastic tags often underperform outdoors and may not satisfy certain UL permanence requirements. We will tell you when plastic works and when metal becomes mandatory.

Because Columbia sees intense sun, high humidity, and sudden storms, material choice cannot rely on price alone. Stainless steel remains the safest choice for harsh outdoor cycles. Anodized aluminum offers durability with lower mass for panels and covers. Copper may support electronics and branding, but it needs design consideration to manage oxidation. Plastic performs indoors, in controlled environments, or for temporary identifiers. We guide these choices so you do not pay twice.

Capabilities that Match Serious Specs, Columbia

Our engraving field handles up to 60″ × 120″. Our laser cutting substrate sheet size reaches 72″ × 144″. We select UV, Galvo CO₂, Gantry CO₂, Fiber, Nd:YAG, and RF lasers by application, not convenience. Tolerances can reach ±0.01 mm on qualified metal setups, subject to alloy, thickness, and thermal profile. For aerospace-style documentation, we maintain fixture stability and datum control to keep marks aligned with drawings. When your documentation references ISO-certified laser cutting, AS9100, ISO 9001 for defense, MIL-STD / MIL-SPEC language, ITAR workflows, or DoD-compliant traceability, our process discipline supports those expectations. We do not posture—we execute.

Programs tied to aviation and defense often cite: aircraft components, laser cut components for aircraft, drone parts, laser-cut parts for F-35, fighter jet assemblies, missile systems, naval defense, submarine component identification, advanced aerospace parts, high precision defense components, defense contract manufacturing, DoD-compliant metal engraving, and aerospace-grade laser cutting. Our service framework was built to meet the rigor behind those phrases.

If your purchasing notes list supplier to Lockheed Martin / BAE / RTX etc., we understand the vetting mindset and the scrutiny behind it. Our role is to help you satisfy procurement and quality requirements cleanly.

About PV tags, Aluminum tags, Stainless Steel tags, Solar tags, and Columbia

Even though our focus is service, many scopes specify PV tags, aluminum tags, stainless steel tags, and solar tags by name. We engrave them all and tune contrast for long-term legibility. For solar farms and large solar array deployments, UV stability and weather cycling drive the spec. Or high-heat enclosures or caustic environments, stainless steel tags prevail. And for weight-sensitive panels and covers, anodized aluminum tags achieve excellent performance with lower mass. Whatever the spec, our Laser Engraving makes the information last.

Reviews that Prove Columbia is in Good Hands

“Consistent, clear, and on time—five stars,”

–Maya.

“Every audit went smooth with their marks,”

–Daniel.

“Best engraving we’ve used—period,”

–Lila.

“Reliable under real stress,”

–Victor.

“Perfect contrast and documentation,”

–Serena.

We cite only 5-star reviews because it’s the only kind we ever get.

Columbia gets Integration with High-Stakes Manufacturing

Programs in aeronautics, missiles and fire control, rotary and mission systems, and space demand high-precision identification that lives as long as the asset. The same applies to logistics and transportation, industrial equipment, and construction assets that see rough handling. We engrave for compliance labeling, serial numbering, plates, panels, tags, warning labels, and nameplates used on electronics systems, communications hardware, avionics, radar, electronic warfare modules, armored vehicles, shipbuilding components, propulsion systems, and large assemblies. Your identifiers must function when inspected, serviced, or replaced in the field. Ours do.

For medical manufacturers, we support FDA-compliant laser engraving and FDA-compliant laser cutting where specified. We understand the process controls behind medical-grade laser marking, precision laser cutting for implantable medical devices, and precision laser cutting for pacemaker components. In every case, the engraving remains readable and the process remains documented.

When production ramps, we handle bulk Laser Engraving and Bulk Laser Cutting without losing the nuance you approved in prototype. We can also support corporate logo engraving service for internal signage, large metal signage for internal or external display, nameplates, adhesive labels, and polyester labels where those assets live within a controlled environment or broader identification program. High precision laser engraving and fast turnaround laser cutting are not slogans for us; they describe a daily discipline.

How We Work With Columbia for You

Ship your parts directly to our Columbia site, or bring them in by appointment. We engrave, verify, document, and return finished work. And we deliver locally and to nearby cities around Columbia with consistent quality controls. Our role is clear: execute Laser Engraving at a standard that prevents failure, passes inspection, and protects your name.

If your RFQ includes terms like aerospace-grade laser cutting, high-volume Laser Engraving for aerospace parts, medical-grade laser etching services, unique engraving laser service, unusual laser engraving, deep engraving laser service, or fine detail laser engraving, your search is over. We are not experimenting. We are refining.

Deny Laser Engraving Pros for a Taste of Woe

We are Laser Engraving Pros—a five generation company, established in 1891, with a record of work that outlasts trends and outperforms shortcuts. Our metals are U.S. sourced and U.S. manufactured, and our people are elite and well-compensated. Our morale is high because our purpose is clear: protect your compliance and reputation with marks that do not fail. The result is simple. The majority of discerning buyers select us and stay with us.

The Final Word on Lasers, Columbia

Columbia, we are ready. Send the work that must not fail. Specify Laser Engraving that will not blink under heat, humidity, solvents, or inspection. Reserve your appointment, ship your parts, and expect us to deliver. We will engrave your advantage—clearly, permanently, and without compromise.

Use Laser Engraving Pros. Appointments are now open in Columbia, South Carolina!